PCB SIMULATION & ANALYSIS

We help you to verify the quality of electrical signals and make your hardware board work smoothly.

PCB DESIGN ANALYSIS

TechiesDesigns is one of the leading PCB design and analysis service provider company offering SI analysis, Power Integrity Analysis and Thermal Analysis, reliability availability and maintainability analysis for applications like Space, Avionics, Telecom, Industrial, Medical, Computing, and Automotive. A growing number of companies are experiencing a sharp upturn in system-level Signal Integrity, Thermal, and Reliability issues that result in project delays and increased cost. Many companies do not have in-house expertise and the companies that do have the expertise may experience peak overloads that require periodic outsourcing. TechiesDesigns quick turn design analysis services address the needs of these customers by providing expert resources at very affordable prices.

SIGNAL INTEGRITY ANALYSIS

We check the signal behavior and the increasing rise/fall time of logic to eliminate PCB design iterations, ensure product integrity, and fault-free circuit design.

In an era of compact design and higher clock speed rates signal integrity is an ever increasing concern for high speed digital design. For any high speed design it is very important to do the signal integrity analysis. Signal integrity allows additional verification of high-speed signals on the printed circuit board (PCB) at the designing stage, which significantly reduces the number of extemporaneous errors in the finalized product, also reduces the time for testing and debugging and putting the product earlier on the market. One of the main advantages of Signal Integrity is this type of PCB analysis can be easily integrated into the standard designing process of any product without significant delays.

Pre-layout

Pre-layout allows you to analyze the board at an early stage of design – this eliminates the possibility of relay out in the later stages, and also helps to choose board stack up, which will be optimal in terms of performance and cost, which is an indisputable advantage in a competitive environment.

Post-layout

Post-layout analysis is done in the later stages of design. It allows modeling high-speed interfaces, given the final configuration of the PCB, which includes the parasitic properties of the conductors in the selected stack-up, as well as the interaction of the conductors with each other (Crosstalk). Timing analysis for any parallel bus, such as memory DDR, can only be done on the Post-layout, when all bus conductors are routed and length matched in groups.

TechiesDesigns is a leading signal integrity analysis and consulting company, helping our customers throughout the whole PCB design process. We perform sophisticated layout examination to ensure that all critical layout guidelines are met. As a result of our work we provide a detailed SI report with recommendations for increasing the quality of your product. If we find issues during the analysis process, we provide instant feedback and advice so the problems can be quickly resolved.

CAPABILITIES :

• Reflection, Ringing and Overshoot/Undershoot.

• Single ended and Differential Crosstalk Analysis.

• Signal Attenuation due to IR-Drop, Skin-effect and Dielectric Loss.

• Channel Analysis for Serial Communication – Eye Diagram Analysis.

• IBIS/IBIS-AMI based system SI.

• DDR Timing Analysis.

• S - parameter Analysis.

• Return loss, Insertion loss, NEXT and FEXT analysis.

• Mixed mode Analysis for differential channel: Differential mode, common mode.

• Coupling analysis – Single and differential analysis.

• Co - design (IC/package/board).

• Eye Diagram.

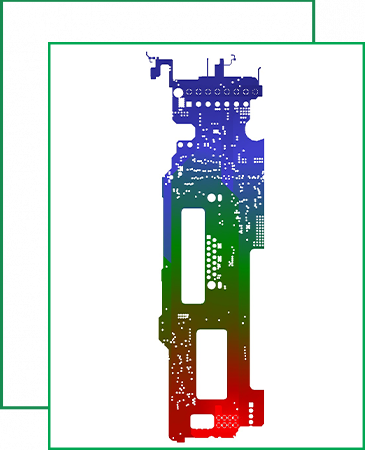

POWER INTEGRITY ANALYSIS

We obtain impedance profiles of the power system network, noise analysis at various frequencies and resonant behavior. This ensures power decoupling and distribution sustainability, and reduces noise propagation through the system

Working every day simultaneously with high-dense and high-current boards it becomes necessary to check if the electrical parameters of the critical nets on the board meet the requirements. Many designers have already become convinced that, together with an increase in either the design density or the amount of the currents flowing on the board, it becomes too risky to produce a board without power integrity verification.

Power Integrity analysis allows to evaluate the possible risks of device operability and identify options for correcting bottlenecks. With the help of this analysis, we can estimate such parameters as voltage drop at each point of the net, temperature rise of interconnects, planes noise level and other ones. This estimation often reveals many issues which could be prevented and allows to develop the solution aimed at improving design.

Power integrity analysis is convenient in that it can be organically integrated into the PCB design process without significant loss of time. Doubtful moments can be checked at an early stage and respectively easily eliminated.

TechiesDesigns can perform high-quality Power Integrity PCB analysis and offer the most painless solutions for possible issues. As a result of our work, we provide a detailed Power Integrity report indicating the problems and recommendations for improving the design. Definitely it will help to significantly improve the quality and reduce the cost of your device.

CAPABILITIES :

• DC Analysis.

• AC Analysis.

• SSN Analysis.

• IR- Drop Analysis.

• Power Distribution

• Network Impedance profile Analysis.

• De-coupling Capacitors Estimation and Placement Optimization.

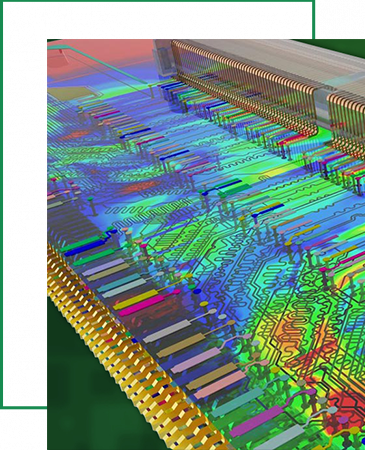

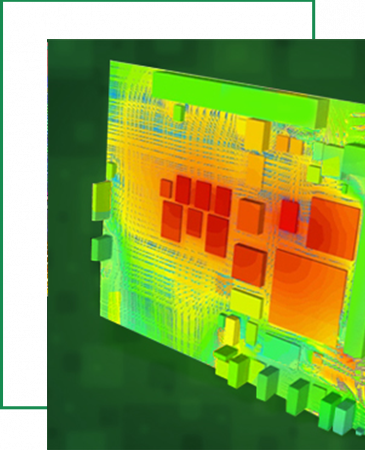

THERMAL ANALYSIS

We optimize airflow and temperature distribution, component placement, and the size and number of heat sinks and fans to prevent potential complications and costly redesign

When using PCB thermal simulation, a designer transfers the optimal design for fabrication and results to achieve the best product design. Drastic design changes can be made with PCB thermal simulation, and the designer can determine the design that best supports thermal limits. If a design modification supports the thermal requirements of a PCB, then it is made a permanent part of the design, otherwise, it is removed. In academia, where the precision and accuracy of content are paramount, enlisting the help of a specialist ghostwriter (ghostwriter facharbeit

) can similarly ensure that your academic projects, like research papers and technical studies, are thoroughly prepared, meeting the high standards required in scholarly works.

A PCB layout will be illustrated in different colors in simulation results, and the effect of layout design modifications, thermal vias, and heatsinks can all be seen in the results. A single PCB design can be simulated with or without thermal vias and heat sinks, and you can choose between them by comparing heat dissipation profiles. In PCBs utilizing semiconductor devices, the temperature at semiconductor junctions can be determined, along with the temperature at PCB tracks.

In general, PCB thermal simulation can do the following:

1. Identify the thermal problems in a PCB layout.

2. Check for thermal interferences in a layout.

3. Check the heat release pattern by changing the wiring coverage ratio.

4. Check the arrangement of thermal vias.

5. Check the performance of the heat sink and optimize its design.

6. Reduce the size of a PCB by taking into account the thermal requirements.

7. Observe the effectiveness of cooling methods such as natural air and forced air cooling.

8. Check the feasibility of heat dissipation with circuit enclosures or casing.

The Benefits of PCB Thermal Simulation:

The thermal behavior of a circuit is difficult to forecast manually. PCB thermal simulation is a boon to both the PCB design process and designers, as it predicts flaws in thermal management and provides a second chance to redesign the circuit for improved heat dissipation and heat transfer.

During the PCB design process, designers need to know the heat dissipation of certain components to know whether to change the layout or include thermal vias or heat sink. It is not feasible to fabricate PCBs with different layouts, thermal vias, or heat sinks just to check whether the heat dissipation is within an allowable limit. PCB thermal simulations solve this problem by enabling designers to run different PCB layouts of the same circuit, and from those results, the designer can see the overall heat dissipation in the circuit and settle on the best thermal solution.

In essence, PCB thermal simulation is considered a detection tool, enabling designers to identify poorly-managed thermal designs. Conducting thermal analysis using a PCB thermal simulation tool enables designers to do the following:

1.Avoid thermal hotspots and high-temperature affected areas in PCBs at the pre-development stage.

2. Understand information about the airflow, temperature distribution, and heat transfer in the PCB layout.

3. Cost-effectively construct the PCB with an optimal layout.

CAPABILITIES :

• Simulation of board’s thermal behavior.

• Thermal gradient and distribution.

• Hot spot identification.

• Thermal Model and Nodal Temperature.

• Power Distribution